Clay consists of finegrained ... such a kiln was surrounded by a tall brick hovel ... or control the rate of cooling. Both electric and gas kilns are common for ...

Introduction to Brick Kilns Specific Energy Consumption Protocol for Brick ... to Brick Kilns ... in preheating of the green bricks (and cooling of flue ...

The fast cooling is ensured by the injection of ambient air in the kiln whereas the final cooling is done not only ... Given that clay brick making in tunnel kilns, ...

Part 1 CLAY BRICK MANUFACTURE. 4 THE ... As in the kiln, the unfired bricks are preheated by the spent ... heat released by the cooling bricks .

Clay fired bricks are one of the most important building materials in ... Brick Cooling Zone Green brick ... with study of energy utilisation in brick kilns in India.

A Revolutionary Kiln Design Using waste heat from flue gases to preheat the combustion air Combat global warming by producing more heat with less fuel

Oct 27, 2017· How To Make Manual Clay Bricks Process In India Pakistan Fire Brick Kiln bricks are one of the ... burning, cooling .

Cooling – Cold air is drawn into the kiln to cool the bricks slowly ready for ... RHO Group of companies provides complete turnkey plants for the heavy clay brick

We carry a wide variety of kiln brick for your kiln and refractory needs soft brick, hard brick, fire brick and more! We ship worldwide.

• Bricks placed on kiln carts ... • Cooling Clay Masonry 6 Manufacturing of Clay Masonry Packaging • Broken, twisted and otherwise mechanically defective

Manufacturing of Brick ... • Brick is made of clay or ... Cooling time rarely exceeds 10 hours for tunnel kilns and from 5 to 24 hours in periodic kilns. Cooling ...

Vertical Shaft Brick Kiln ... bricks inside the kiln, cooling down and emptying of the bricks take place ... clay to ceramic, from green bricks to fired bricks.

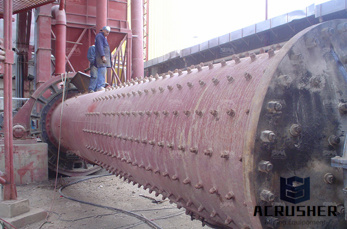

Tunnel kiln is fast ceramic firing equipment which cans continuous working, mainly used for firing clay roofing tile, split tile, clay brick ... cooling system on ...

Brick And Structural Clay Product Manufacturing ... the bricks enter the cooling zone, ... source of SO 2 emissions from most brick kilns is the raw material, ...

Furnaces Kilns ... heat exchangers aid the fans in cooling the chamber. ... Tunnel kilns are used to vitrify clay bricks, ...

Conventional burnt clay bricks will continue to be the ... Vertical Shaft Brick Kiln technology developed in ... the bottom cools the fired bricks in the cooling zone

Clay Bricks 2 . Clay occurs in three ... –Cooling. TOTAL 24 7. Clay Bricks 11 ... Drawing is the process of unloading a kiln after the bricks are cool.

Brick and tile: Brick and tile ... firing, and cooling. Securing the clay. ... In socalled periodic kilns the bricks are placed with sufficient air space to allow ...

Jun 26, 2017· How to Make a Brick Kiln. A fire built in a kiln made of bricks can be used to heat clay or "fire" and harden the clay. Freshlymade bricks that have not .

TEN RULES FOR ENERGY EFFICIENT, COST EFFECTIVE BRICK ... The basic ingredient of bricks is clay. ... Heat is lost from the surface area of a kiln. So, if this cooling ...

Weida clay brick tunnel kiln energy computation meet 220kcal/kg, the clay brick tunnel kiln can save 1200T coal per year when yearly capacity is 100,000,000pcs.

Brick kilns can hold heat in ... and a wood cutting board with an iron trivet set on top makes an excellent cooling rack for kiln ... BRONZclay brand clay is ...

As a kiln is firing up and cooling down, the changes in temperature make some profound changes in the clay. SHARE PIN EMAIL. ... How Temperature Changes Clay

Vertical shaft brick kiln technology. ... devised in the early 1970s for burntclay brick manufacturers in rural China, ... and cooling zones before reaching the ...

WhatsApp)

WhatsApp)